Key Points Summary

Manufacturing Revolution: BMW's Debrecen plant represents a paradigm shift in automotive production, achieving just 0.1 tCO₂e per vehicle, nearly 85% lower than conventional BMW facilities

Lifecycle Leadership: The iX3 Neue Klasse delivers up to 72% lower lifecycle emissions than comparable ICE vehicles, with breakthrough battery technology enabling 800km WLTP range and 400kW charging

Circular Economy Integration: Advanced material circularity achieves 35% CO₂ reduction in manufacturing through recycled content strategy and "design for disassembly" principles

Introduction: Beyond the Tailpipe Debate

The automotive industry, ICE car owners, EV drivers, and enthusiasts are locked in the same emissions debate.

On one side are those who focus on tailpipe emissions, declaring EVs "zero emission." On the other side are those who point out, sometimes with a smirk, that building an EV is anything but environment friendly and it is even more damaging to planet compared to ICE cars.

The truth lies in a bigger picture. The only way to answer the question "Which is cleaner?" is to measure a vehicle's entire lifecycle or Life Cycle Assessment (LCA). That means counting emissions from raw material extraction, to manufacturing, decades of driving, and finally end of life recycling.

BMW has been doing exactly that and publishing detailed reports. Enter the Neue Klasse iX3, BMW's latest step toward sustainable mobility. On paper, it claims a 35% reduction in total CO₂ emissions compared to its baseline manufacturing footprint. Against its gasoline counterpart, it cuts lifetime CO₂ emissions by 56% to 72% over 200,000 km, reaching carbon parity in as little as 17,500–21,500 km.

And here's something I appreciate: BMW publishes these figures for both EU average grid charging and renewable electricity, showing exactly how infrastructure changes the outcome.

The timing of iX3 Neue Klasse couldn't be more relevant. Regulatory pressure is increasing, ESG targets are tightening, and OEMs are racing to make not just greener cars, but greener production. Let's see how BMW is trying to set the benchmark.

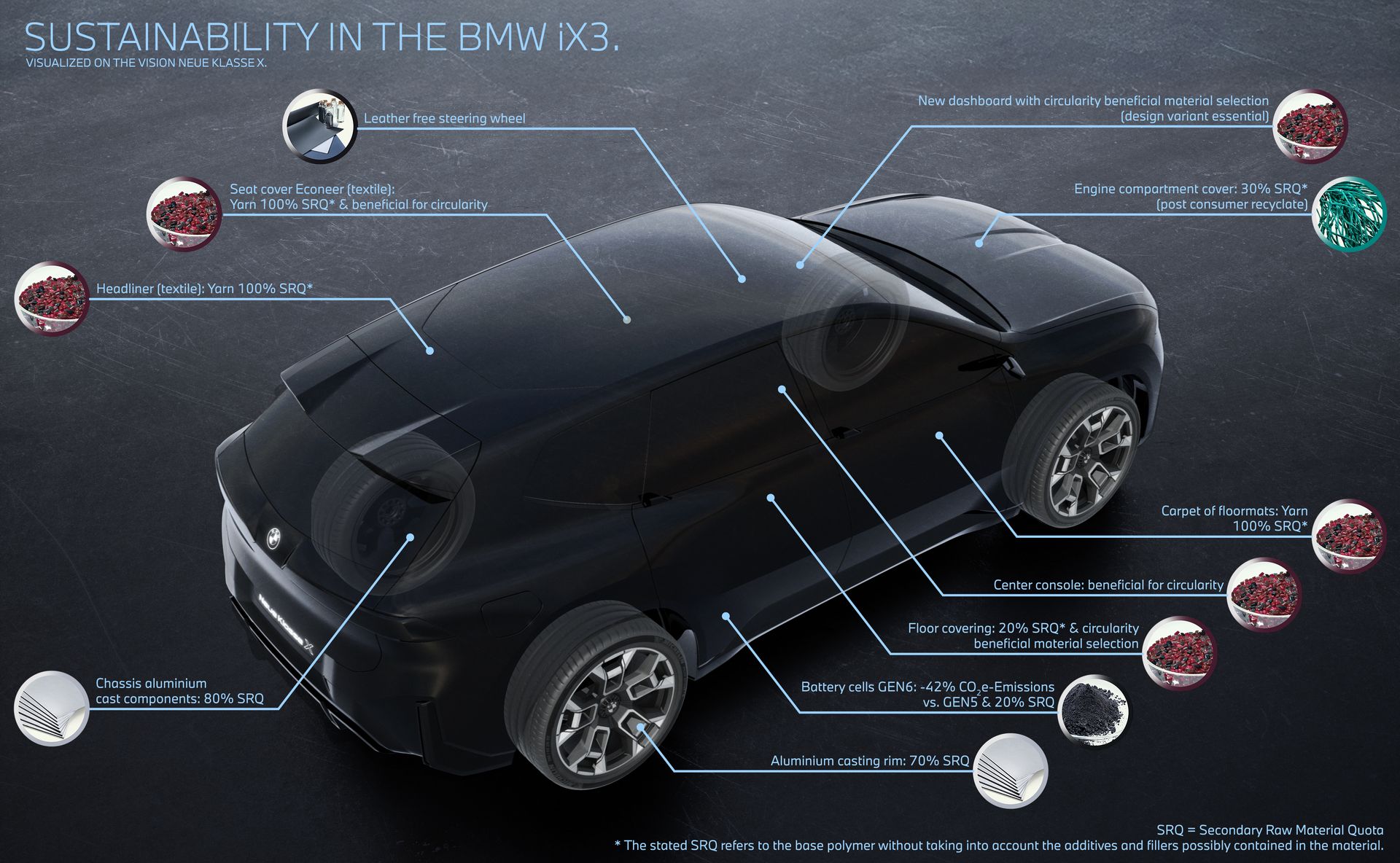

Sustainability Sources in the BMW iX3 (Source: BMW)

The Grid Reality: Why the Same EV Can Be a Champion or Just "Good"

Before diving into BMW's iX3 numbers, it's important to understand the role of a country's energy mix. For this let's look at an example from another part of the industry, heavy trucks, to understand just how much the grid matters.

Take Daimler's comparison of a Mercedes Diesel vs eActros 600 electric truck.

Same electric truck. Same battery. Same mileage. Yet there's a 93% difference in climate impact depending on where it's charged and driven.

The calculation assumes 10 years of use, 120,000 km per year, that's 1.2 million km total.

The diesel truck emits 944 tCO₂e over its lifetime.

The eActros in Germany emits 26% less than diesel.

The eActros in Norway emits 96% less than diesel.

Compare Norway to Germany and the difference is a staggering 93%. That's huge. But why? Because Norway's grid is almost entirely renewable with 89% of energy coming from hydroplants, while Germany still relies on fossil fuels for approximately 46% of its energy mix.

This isn't a failure of the technology, it's proof that infrastructure is part of the product. The cleaner the grid, the more the EV's manufacturing "carbon investment" pays off. I will discuss this topic in detail in the coming editions.

In BMW's case, that's exactly why they publish both EU-average and 100% renewable charging scenarios. It makes their data more realistic, and more transparent.

How BMW Calculates Lifecycle CO₂

BMW's LCA breaks down into four key phases, the only way to see the real environmental impact of a car:

Raw Material Extraction: Mining, refining, and processing metals, plastics, and battery minerals. This is where EVs face their initial carbon investment due to battery cell production.

Vehicle Production: Body manufacturing, assembly, and energy source of the plant.

Use Phase: Fuel or electricity consumed over the vehicle's life. For ICE cars, this is where the majority of emissions happen. For EVs, this is where your grid mix decides whether you're seeing good or great results.

End of Life & Recycling: Dismantling, material separation, and supply chain reintegration. BMW's "design-for-circularity" approach with 33% recycled content vehicle wide positions them well for this increasingly important phase.

BMW Life Cycle Assessment Methodology

Technical Excellence: What Makes the iX3 Different

The Neue Klasse platform marks BMW's most ambitious leap in eMobility so far, and the iX3 stands as its flagship example of engineering performance and sustainability in harmony.

At its heart is the Gen6 battery system, which moves from prismatic to cylindrical cells, a change that boosts energy density by 20% while cutting CO₂ emissions per kilowatt-hour by an impressive 42% compared to BMW's previous packs. The Gen6 battery cells of the BMW iX3 high-voltage storage system are made of 50% secondary cobalt, lithium, and nickel materials. With a net capacity of 107.9 kWh, it enables more than 800 km of WLTP range without upsetting the vehicle's weight balance or handling.

Gen6 cylindrical battery cell production at Debrecen plant: Source - BMW

Built on an 800 Volt electrical architecture, the iX3 can sustain peak DC charging of 400 kW over a wide state of charge window. Advanced thermal management prevents the steep mid-charge slowdown that plagues many EVs, meaning drivers can add roughly 350 km of range in just 10 minutes under optimal conditions and charger availability.

The iX3 also debuts bidirectional charging with a 19.2 kW DC output, unlocking full Vehicle-to-Grid (V2G) capability as well as support for Vehicle-to-Load (V2L) and Vehicle-to-Home (V2H) applications. This means the iX3 is not just a vehicle, it's a potential backup power source and a grid asset, unlocking options to earn money by selling energy back to the grid.

Gen6 battery production at Debrecen plant: Source - BMW

iX3 vs. Gasoline Counterparts LCA: Where the Break-even Happens

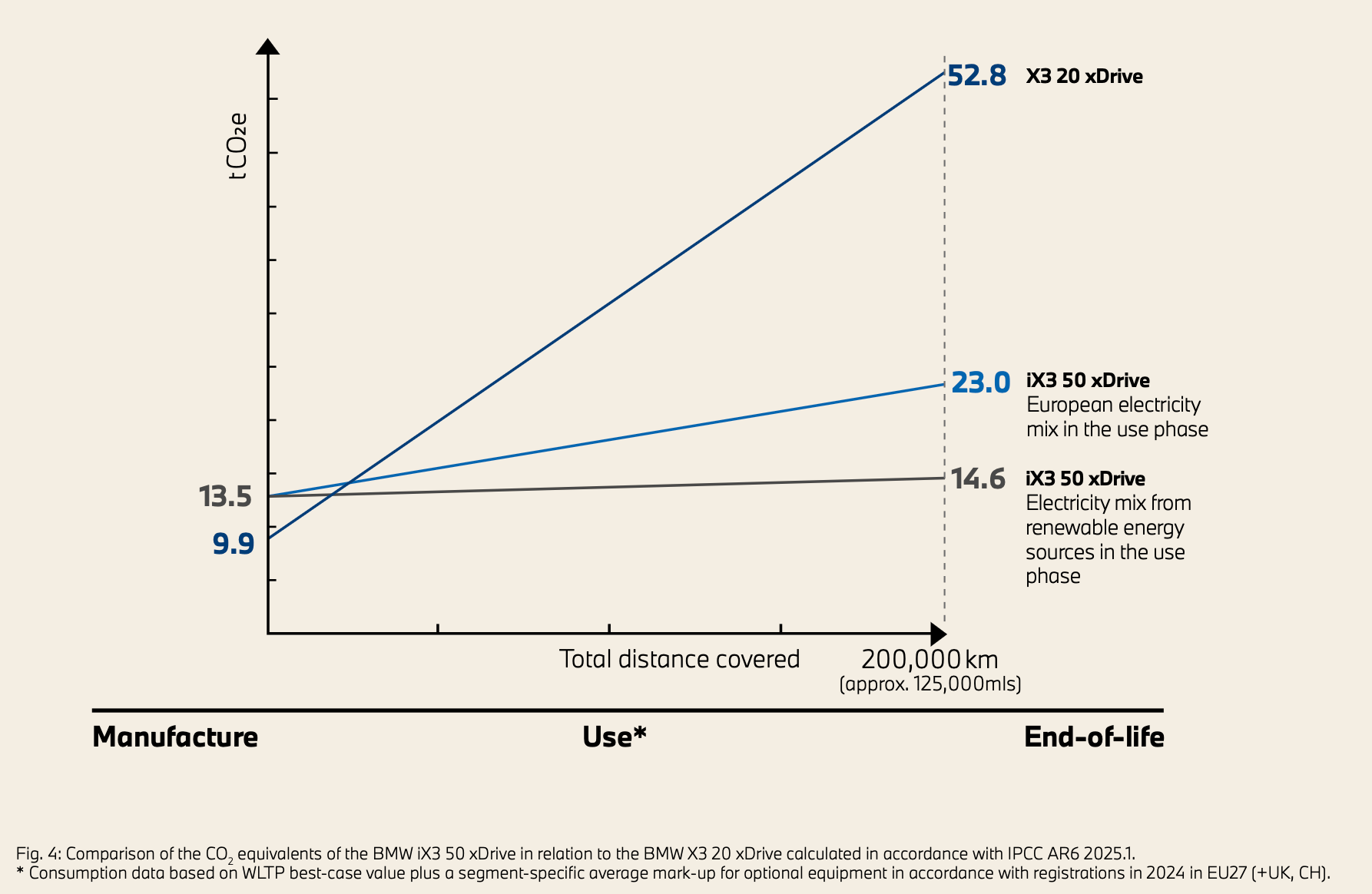

LCA Comparison: iX3 Neue Klasse vs X3 20 xDrive (Source: BMW)

BMW's LCA shows:

EU grid charging: Parity with X3 ICE at ~21,500 km. Over 200,000 km, 56.5% lower CO₂ emissions.

100% renewable charging: Parity at ~17,500 km. Lifetime emissions drop by 72.4%.

Why this matters: An average driver in Germany covers approximately 12,320 km every year.

For most private owners, both parity points happen within the first 1.5 to two years of ownership. For fleets, the payback is even faster given higher mileage, and they might break even within a year.

How BMW Is Achieving These Reductions

When you break down BMW's numbers, it's clear that most of the progress in lowering lifecycle CO₂ is happening before the car ever leaves the factory.

ICE models start with a smaller manufacturing baseline (9-13 tCO₂e), so even with efficiency gains, the absolute reduction is limited.

BEVs start with a larger manufacturing footprint (17-23 tCO₂e) due to battery production, but this also means there's more CO₂ to cut.

The iX3 50 xDrive stands out, achieving not only the largest percentage cut (~35%), but also the biggest absolute reduction of any BMW in the lineup, showing the combined effect of a clean production site and next-gen battery tech.

BMW's headline CO₂ savings aren't just the result of efficient driving, they're being "baked in" during manufacturing.

BMW Manufacturing CO2 Footprint & Savings: ICE, PHEV and BEV

The Two Levers: Recycled Inputs and Clean Power

BMW is using secondary (recycled) materials, like aluminum, steel and critical battery metals (cobalt, nickel, lithium). But they also focus on integrating renewable energy in production, both at BMW plants and in the supply chain (e.g., battery cell factories, aluminum smelters).

For ICE models, most gains come from recycled content, since there's no high-energy battery cell manufacturing to decarbonize. For BEVs, the picture flips - renewable energy becomes the main driver, especially for battery production. The iX3 leads here too, proving how much clean energy sourcing can shrink the footprint of a battery-heavy vehicle.

BMW Manufacturing CO2 Savings: ICE, PHEV and BEV

Debrecen: BMW's Blueprint Factory

At the center of these manufacturing gains is BMW's new Debrecen plant in Hungary, a facility purpose-built for the Neue Klasse era. This site runs on 100% renewable electricity, primarily from its on-site solar power plants and other renewable sources. With this setup, it achieves just 0.1 tCO₂e per vehicle compared to 0.3-0.7 tCO₂e in older BMW plants.

Gen6 battery production at Debrecen plant (Source: BMW)

How Energy Mix Shapes the Full CO₂ Story Across BMW Portfolio

Manufacturing is just the opening chapter of a car's CO₂ story. The real spread happens once you factor in a lifetime of driving, and that's where the grid mix takes center stage.

This comparison across BMW's 2 Series, 3 Series, and 5 Series lineup reveals how dramatically charging infrastructure affects EV payback periods. Size matters, but not how you'd expect. The larger, more premium vehicles face longer break-even timelines due to their bigger batteries and higher manufacturing footprint. The 5 Series i5 eDrive40 needs roughly 55,000 km to match its 520i counterpart on EU grid charging, but drops to around 40,000 km with renewable energy, a 27% faster payback. The compact 2 Series shows a similar pattern: the iX2 xDrive30 breaks even with the X2 sDrive20i at approximately 47,000 km on EU grid power, but achieves parity at just 31,000 km with clean charging, 33% faster.

The 3 Series iX3 sits in the sweet spot, delivering substantial battery capacity for long range while hitting reasonable break-even distances that most owners will cross within one to two years of typical driving.

But here's where it gets interesting. When I compared BMW's cleanest BEV (iX3 50 xDrive) against their most carbon-intensive one (iX xDrive 45), the results were eye-opening. The iX3 running on EU grid electricity still beats the iX charged purely with renewables. That's the power of next-generation manufacturing and battery efficiency working together.

The message is clear: once you drive past these crossover points, every kilometer becomes a climate win that compounds over the vehicle's lifetime. Choose your EV wisely, and your charging source even more carefully.

BMW Lifecycle CO2 Footprint - Manufacturing vs Total Emission (2, 3, 5 Series)

Final Thoughts

The Neue Klasse iX3 from BMW is proof that EV sustainability is about more than tailpipes. BMW has combined strong engineering, smarter manufacturing, and transparent reporting to set a benchmark.

But, and this is the key takeaway, your charging source decides whether that benchmark result is good... or game-changing.

As grids decarbonize, the iX3's advantage will only grow. And for anyone lucky enough to already have clean energy access, this SUV delivers on the "zero emissions" promise in a way few vehicles today can match.

Open to Consulting & Collaborations

I'm currently open to:

Consulting and advisory roles

Strategic projects in eMobility

Industry panels and data-driven content partnerships

If you're working on something where pricing strategy, charging infrastructure, or EV market positioning matters and you're looking for someone who combines industry insight with user-focused thinking, I'd love to hear from you.

Let's bring meaningful change to this space together.

That's it for today. If you found this useful, or have other examples from your own driving or data analysis, I'd love to hear them.

📩 To stay ahead of the eMobility curve and automotive news, subscribe to my newsletter, follow me on my socials (Linkedin, Youtube, Podcasts etc.) to get latest insights on emobility, automotive news and global market strategy.

Haseeb